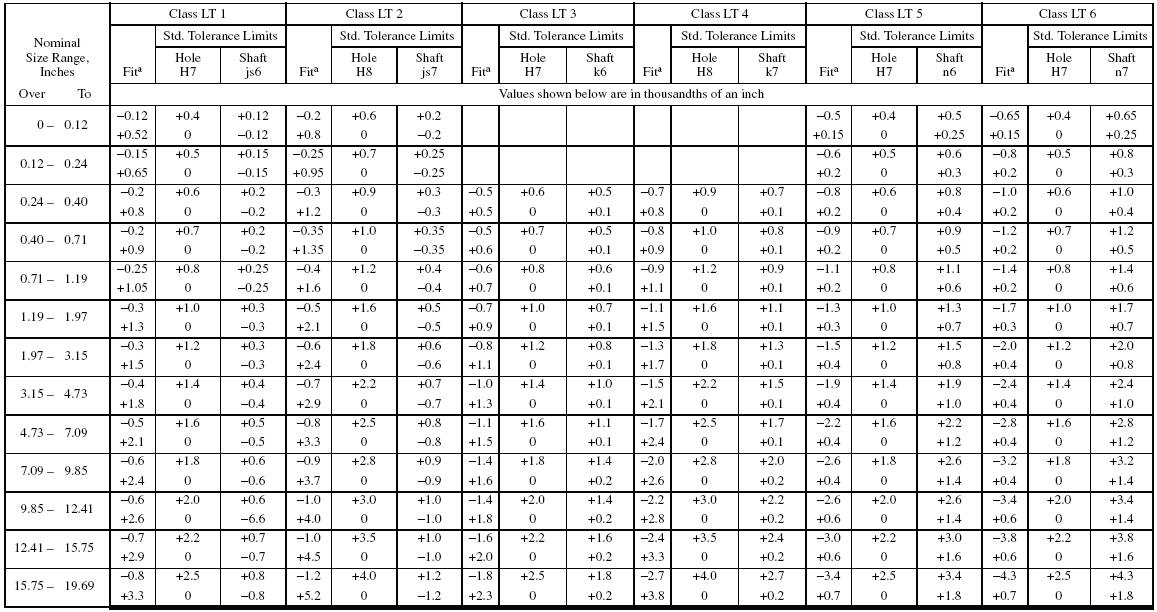

But to me it seems like unnecessary information. So I think that is why there is no shaft size for the ABC LC11 equivalentīecause the ASME B4.1 standard has not been updated since 1967, this info is still shown in Machinery’s Handbook. – A selection of fits made by recommended association of certain of the holes and shaft, the selection being adequate to cover most engineering requirements.

H7 H6 FIT TOLERANCE SERIES

– A series of shaft, one of these limits being determined by the allowance (according to some technical requirement), the other being derived from it by addition or subtraction of the fundamental tolerance. – A series of unilateral hole limits derived from the fundamental tolerances, for use with a hole basis system. – A grade system of fundamental tolerances for diameters 0.04 inch to approximately 20 inches, the tolerance values in each grade being to the diameter by a given law of formula and each grade of tolerance being approximately related to the others in the system in a preferred number ratio (R5 series, with 60 percent increments). This ABC recommendations cover some common ground but isn’t everything.

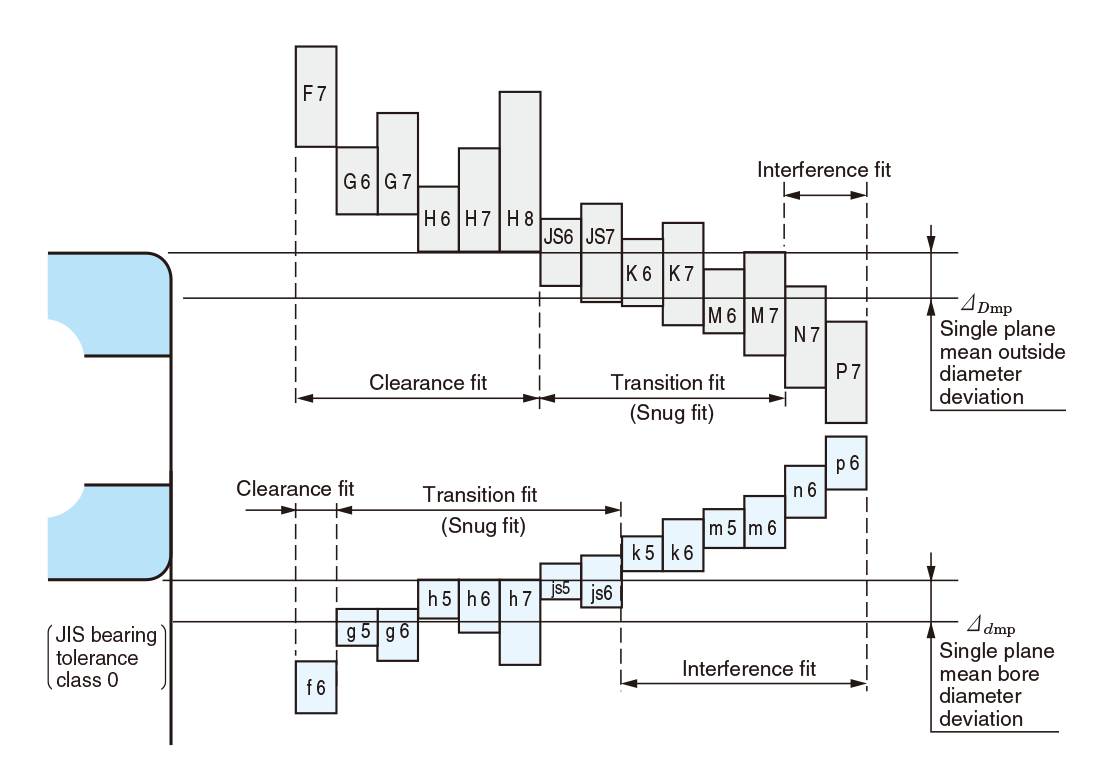

H7 H6 FIT TOLERANCE ISO

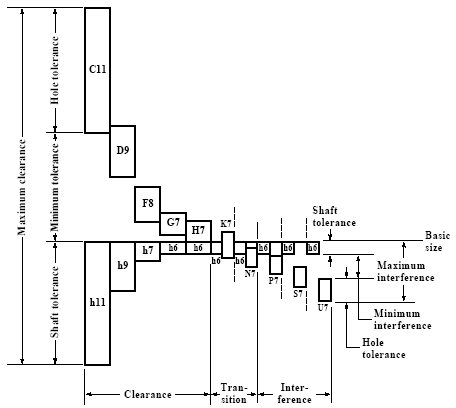

This was before ISO 286, but I am not very familiar with the history of the metric standards and how the ABC recommendations fit into it. In the forward of ANSI/ASME B4.1-1967 they talk about the ABC conferences and the recommendation from conferences in the 1940s-1960s to implement a common reference between the three countries. in this table are referencing the ABC (American-British-Canadian) Hole and Shaft agreement. Referencing 2:19 in the video showing Machinery’s Handbook with ASME fits and there is no hole designation for LC 11 shaft The hole/shaft symbols “H10, g9” etc. Reference Machinery’s handbook, or ISO 286-2.Įxamples of six different types of common fits, and some general guidelines for The naming convention isĭifferent, but the general concept is the same. System, but there is a similar convention for metric.

This video deals primarily with ASME fits in the inch The letters denote the type of fit, and the numberĬorresponds to the tolerance class of the fit, with larger numbers representing Two-letter abbreviation followed by a number.

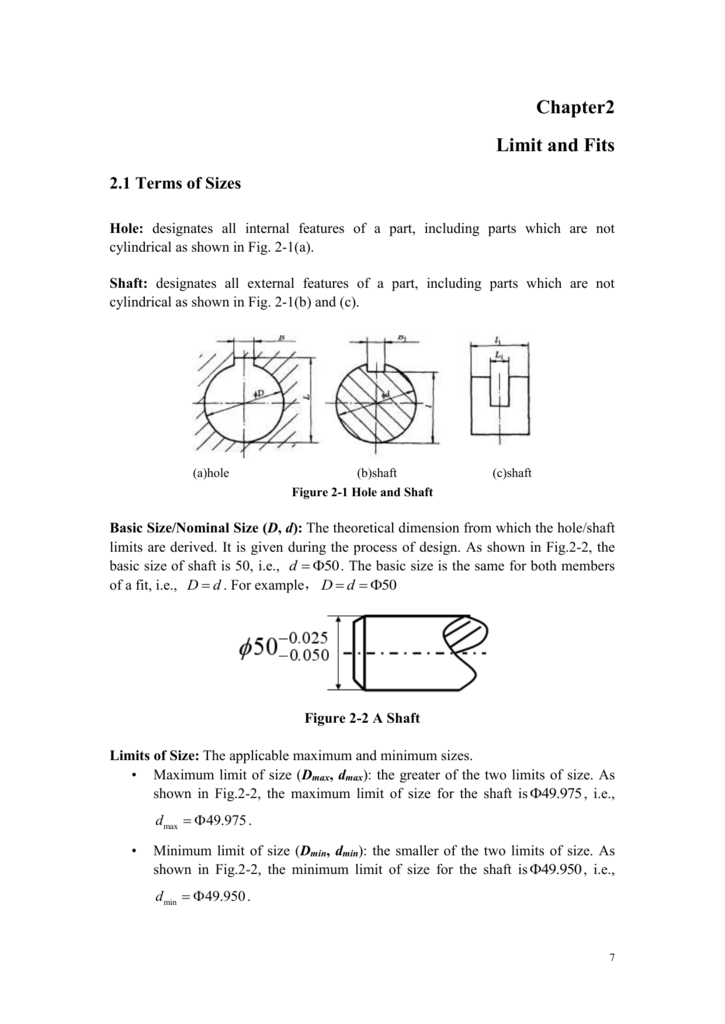

Fits have a particular naming convention of a You mightĮven need to have two components come together permanently and not come apart. In other cases, lots of relative movement is okay. You might want components to slip easily together, but not have a lot of Need? Tolerances typically come into play when designing fits. Tighter, the cost to manufacture the part grows exponentially. Tolerances that are far tighter than necessary. A very common mistake that new engineers make is selecting Machine wear, deflection, sharpening, and the natural variation of different It’s important to remember that toleranceĬapability corresponds to a large production run, where factors like tool and Variation from our nominal dimension is acceptable.Īre capable of different tolerances. “tolerance” which tells the person manufacturing the part how much of a The number we originally typed into the computer.

Each feature might be slightly larger or smaller than To actually make that part, we won’t be able to manufacture the features toĮxactly those dimensions. Time, especially in CAD, we just type single, exact numbers into the computerįor our dimensions. They fit together exactly the way you want on the first try, every time, and inĬonsideration is “fits and tolerances”. There’s a systematic way to design parts so Sometimes you needĬomponents to slip together easily, while other times, you need components to Products have multiple components that need to fit together.

0 kommentar(er)

0 kommentar(er)